2018-2019

GYARADOS & MAGIKARP ~ (Senior Design & Club Team)

| POSITION | NAME | MAJOR |

|---|---|---|

| Team Captain / President | J.Diego Santillan | Electrical Engineering |

| Frame and Motion | Kevin Tran | Mechanical Engineering |

| Torpedo System Lead | Andrew Lopez | Mechanical Engineering |

| Frame Design Lead | Alan Truong | Mechanical Engineering |

| Hull Design Lead | David Garcia | Mechanical Engineering |

| Communications Lead | Albert Le | Electrical Engineering |

| Hydrophones | Aldo Madrid | Electrical Engineering |

| Apprentice | Sidra Gibeault | Electrical Engineering |

| Computer Science Lead | Olin Alvarez | Computer Science |

| Computer Science Team | Jonathan Song | Computer Science |

| Computer Science Team | Danny Padilla | Computer Science |

| Computer Science Team | Henry Ho | Computer Science |

| Computer Science Team | Ethan Cha | Computer Science |

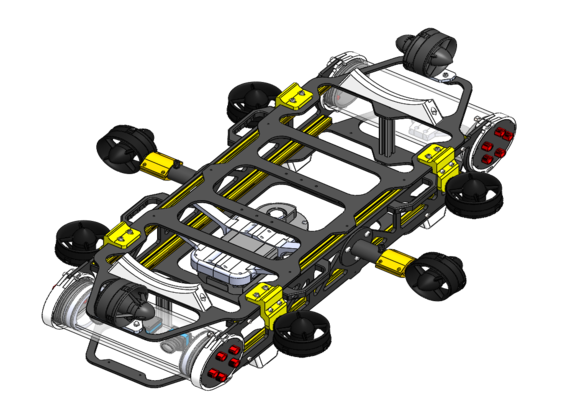

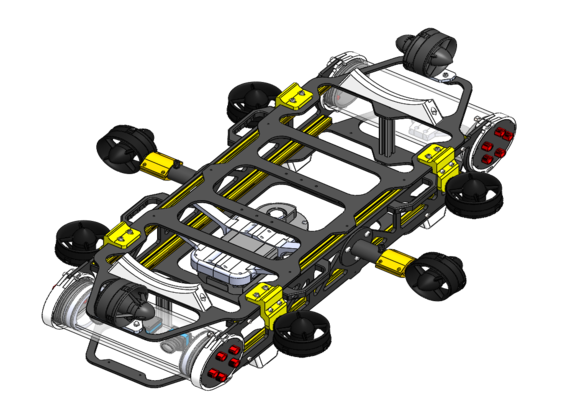

Gyarados consists of a mechanical frame and hull, as well as a servo controlled mechanical arm, torpedoes, and dropper mechanism.The frame consists of waterjet and anodized aluminum, along with 3D printed brackets for mounting waterproof enclosures, thrusters, and the DVL. The frame includes 4 aluminum t-slot rails that are used as corner brackets for mounting together the baseplates and the sides. The rails duly function as a mounting point for the other sub-systems.

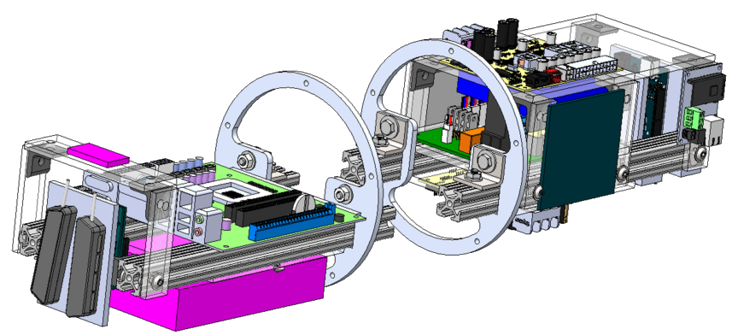

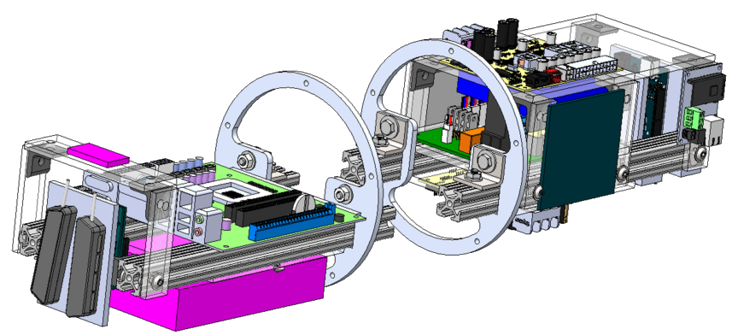

The waterproof hull was manufactured in 2018 and consists of two 8" diameter acrylic tubes connected to a custom machined aluminum bulkhead. The bulkhead contains 18 SEACON connectors for electrical interfacing. On each end are aluminum endcaps, and several 3D printed parts are used on the hull for mounting latches. The latches serve as an extra degree of leakage protection, in addition to the double o-ring seals on either side of the bulkhead. The tubes on each end of the sub can be removed from the bulkhead, leaving the electronics stack exposed. Gyarados hull: Two 4" diameter acrylic tubes are also present on either end of the submarine to serve as the waterproof enclosures for the cameras and batteries.

In 2018, the electronics shelving was a simple acrylic shelving system held together by nuts and bolts. In 2019, this shelving system was redesigned to consist of a custom manufactured aluminum flange for the inside of the bulkhead and 6061 t-slot aluminum to hold acrylic sheets in place to serve as shelves. These shelves utilized more of the available space inside the hull, allowing the addition of extra electronic components for Gyarados' second year competing. The updated shelving is shown below.

Gyarados did not feature a working claw or dropper, but its torpedo system was functional.The torpedo system was a servo mechanism that would launch the torpedo on command. The team waterproofed its own servo motors using several commercially available products.

While it was unsuccessful, the 2019 team worked on the development of a mechanical claw with a small waterproof enclosure for a linear actuator and a dynamic o-ring seal. The waterproofing of this system failed, but the system was functional outside of water. Future systems opted to waterproof the servos/actuators themselves rather than creating enclosures, since waterproofing a shaft opening is difficult and prone to failure. The team is still investigating ways to create waterproof enclosures for servo motors and actuators.

While it was unsuccessful, the 2019 team worked on the development of a mechanical claw with a small waterproof enclosure for a linear actuator and a dynamic o-ring seal. The waterproofing of this system failed, but the system was functional outside of water. Future systems opted to waterproof the servos/actuators themselves rather than creating enclosures, since waterproofing a shaft opening is difficult and prone to failure. The team is still investigating ways to create waterproof enclosures for servo motors and actuators.

The waterproof hull was manufactured in 2018 and consists of two 8" diameter acrylic tubes connected to a custom machined aluminum bulkhead. The bulkhead contains 18 SEACON connectors for electrical interfacing. On each end are aluminum endcaps, and several 3D printed parts are used on the hull for mounting latches. The latches serve as an extra degree of leakage protection, in addition to the double o-ring seals on either side of the bulkhead. The tubes on each end of the sub can be removed from the bulkhead, leaving the electronics stack exposed. Gyarados hull: Two 4" diameter acrylic tubes are also present on either end of the submarine to serve as the waterproof enclosures for the cameras and batteries.

In 2018, the electronics shelving was a simple acrylic shelving system held together by nuts and bolts. In 2019, this shelving system was redesigned to consist of a custom manufactured aluminum flange for the inside of the bulkhead and 6061 t-slot aluminum to hold acrylic sheets in place to serve as shelves. These shelves utilized more of the available space inside the hull, allowing the addition of extra electronic components for Gyarados' second year competing. The updated shelving is shown below.

Gyarados did not feature a working claw or dropper, but its torpedo system was functional.The torpedo system was a servo mechanism that would launch the torpedo on command. The team waterproofed its own servo motors using several commercially available products.

While it was unsuccessful, the 2019 team worked on the development of a mechanical claw with a small waterproof enclosure for a linear actuator and a dynamic o-ring seal. The waterproofing of this system failed, but the system was functional outside of water. Future systems opted to waterproof the servos/actuators themselves rather than creating enclosures, since waterproofing a shaft opening is difficult and prone to failure. The team is still investigating ways to create waterproof enclosures for servo motors and actuators.

While it was unsuccessful, the 2019 team worked on the development of a mechanical claw with a small waterproof enclosure for a linear actuator and a dynamic o-ring seal. The waterproofing of this system failed, but the system was functional outside of water. Future systems opted to waterproof the servos/actuators themselves rather than creating enclosures, since waterproofing a shaft opening is difficult and prone to failure. The team is still investigating ways to create waterproof enclosures for servo motors and actuators.